2021 Awards Finalists

The KiwiNet Awards celebrate heroes in research commercialisation — those individuals and organisations whose best practice approach is changing the innovation landscape in New Zealand. We congratulate the 2021 finalists!

Momentum Student Entrepreneur Finalists

This award recognises a highly motivated university student who looks beyond the science and sees the prize - how their idea can change the world. The student is making outstanding contributions to business innovation or has created innovative businesses in New Zealand through technology licencing, start-up creation or by providing expertise to support business innovation.

Jeanette Rapson

Jeanette Rapson

Massey University

Early Habits - freeze-dried vegetable baby food

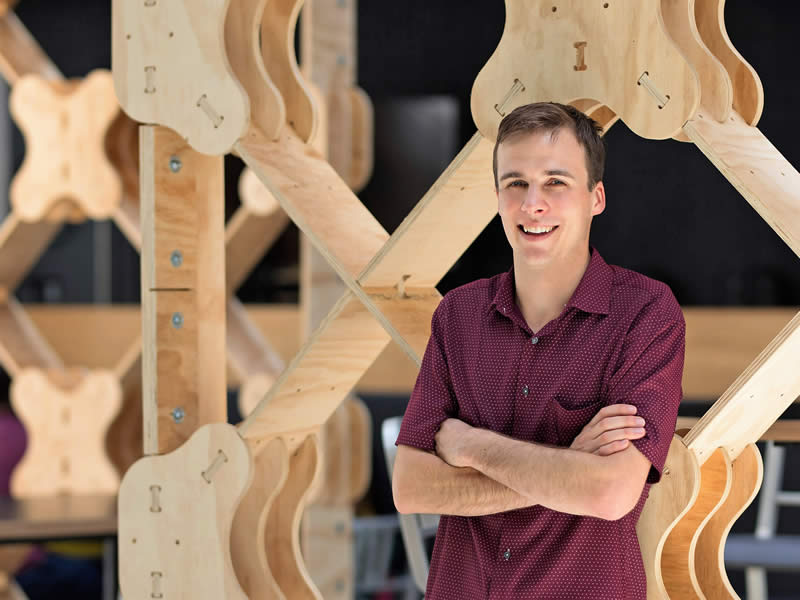

Luke Campbell

Luke Campbell

University of Canterbury

Millions of calls made smarter with Vxt

Tom Maslin

Tom Maslin

University of Canterbury

The next generation of cochlear implant technology

Jeanette Rapson, Massey University

Early Habits - freeze-dried vegetable baby food

Jeanette Rapson, NZ registered dietitian and founder of Early Habits

Massey University PhD student Jeanette Rapson, a registered NZ Dietitian and founder of Early Habits, is an up-and-coming innovator on a mission to help new parents feed their baby nutritious food on-the-go. Through a unique processing method and her deep customer understanding, she will be the first in New Zealand to bring innovative freeze-dried 100% vegetable baby foods to market.

Jeanette’s entrepreneurial journey was kick-started through the 2020 Grand Ideas Competition at Massey University, securing 2nd place for her Early Habits idea. Following this, Jeanette received funding and mentor support through Massey Ventures, taking every opportunity to develop her understanding of business, entrepreneurial networks and give back to the business community. She also pitched her way to success as a finalist in Kiwi Innovate 2020, run by The Factory in Palmerston North – securing a spot on Innovate’s ten-week accelerator programme. Additional support from Momentum and KiwiNet has helped Jeanette realise her passion for innovation and the need to bring her product to life.

Jeanette’s freeze-dried baby food powders contain only vegetables (e.g. broccoli, spinach, beetroot, kūmara, green bean, potato, pumpkin). The sachets are travel/storage friendly with a long shelf-life. With the simple addition of water, the powders rehydrate to smooth baby purées. The freeze-dried method retains the nutrients, flavours and vibrant colours.

Having recently submitted her PhD research on infant nutrition as a student at Massey University and the Riddet Institute; she is now ready to take her innovation further and seize every opportunity to upskill, work with industry and build networks.

Luke Campbell, University of Canterbury

Millions of calls made smarter with Vxt

Luke Campbell, co-founder & CEO Vxt

Luke Campbell, co-founder and CEO of call and voicemail platform Vxt, is studying toward a bachelor degree in Physics and Economics at the University of Canterbury. Luke started the business with co-founder and long-time partner computer scientist Lucy Turner in November 2018. Since launching the company, Luke and the now 17-strong Vxt team has rapidly grown the Vxt business. Luke also dedicates time to encouraging other students to launch their ventures and assists with start-up challenges and hackathons.

Vxt is replacing traditional phone systems with a smart calling and voicemail platform for lawyers, recruiters and professional services. Vxt boasts over 10,000 platform users across the United States, United Kingdom, Canada, Australia, and New Zealand - and has helped customers manage over 2 million phone calls since launching their first service in October 2019. Vxt's customers use the flexible software platform to make calls with business numbers from anywhere whilst automating administrative tasks associated with phone calls, often saving multiple hours per staff member per week.

Vxt is part of the Google Cloud for Startups Programme, the Vodafone Xone Partner Series Programme with BNZ and the prestigious Startmate accelerator programme. The fast-growing company has raised close to one million dollars to date and is currently raising additional funds to enable continued growth. Counting Microsoft, Zoom, Cisco, and many more amongst their competitors - Luke and the team at Vxt are a great example of what a small group of dedicated Kiwis can achieve on the global stage.

Tom Maslin, University of Canterbury

The next generation of cochlear implant technology

Engineers at the University of Canterbury are developing the next generation of cochlear implants using a new method of detecting sound that enables a higher quality of hearing in a fully implantable prosthetic.

Tom Maslin was working as a graduate engineer in robotics and automation before returning to study as a doctoral candidate in mechanical engineering under Associate Professor Stefanie Gutschmidt. Building on a new method of detecting sound validated by Gutschmidt et al., Tom is working to develop the technology into a fully implantable device able to restore hearing above what conventional cochlear implants can achieve.

Almost half a billion people globally suffer from disabling hearing loss1, and cochlear neuroprosthetics offer to restore some of their ability for verbal communication. This generates a still-growing $2.63B NZD industry globally, even as conventional implant users continue to struggle to hear in noisy environments, listen to music, and protect a fragile electrical device on the side of their head.

Perhaps the most significant restricting factor of the cochlear implant is the incredible cost; the ministry of health provides $15 million annually in New Zealand, which can fund only 160 implants per year2, leaving many eligible patients to struggle to find funding themselves. Removing the need for an external unit can decrease the complexity and cost of the surgery creating a better performing device with greater accessibility.

Tom is aiming development to have a device available for in-vivo testing within the next three years and has recently been awarded a place in the KiwiNet Emerging Innovator Programme to develop his understanding of the medical device marketplace, investigate models for going to market and build his knowledge in medical device regulation.

- World Health Organisation. (2021, April 1). Deafness and hearing loss.

- Ministry of Health. (2021, May 19). Cochlea Implant.

Breakthrough Innovator Finalists

This award recognises an upcoming entrepreneurial researcher who is making outstanding contributions to business innovation or is creating innovative businesses in New Zealand through technology licencing, start-up creation or by providing expertise to support business innovation.

Christopher Smith

Christopher Smith

Manaaki Whenua - Landcare Research

The Mushroom Smith - commercial-scale production of fungi traditionally collected and eaten by Māori.

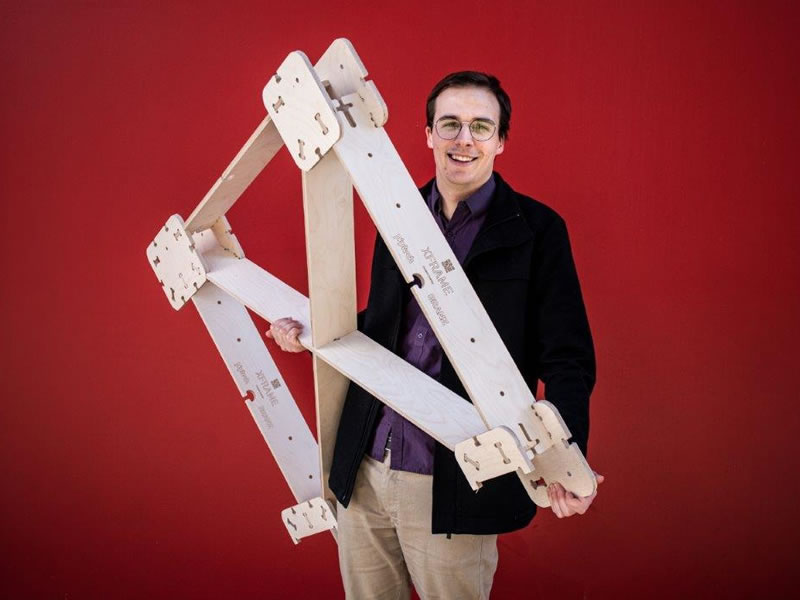

Ged Finch

Ged Finch

XFrame™ Pty Ltd/ Wellington UniVentures

XFrame™ - a recoverable and reusable framing system for the next generation of sustainable construction

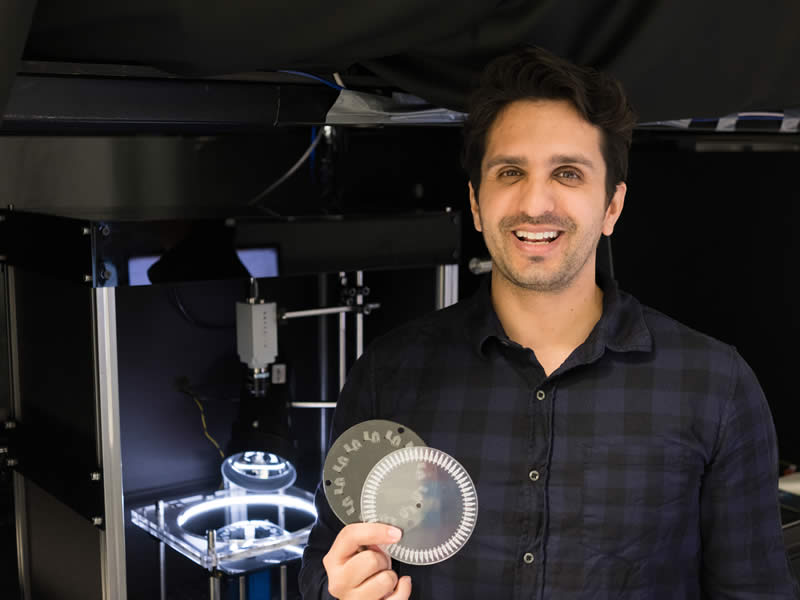

Dr Matheus Vargas

Dr Matheus Vargas

Orbis Diagnostics/ University of Auckland

Orbis Diagnostics makes complex medical testing simple and accessible wherever and whenever needed to help re-enable safe travel amidst a pandemic

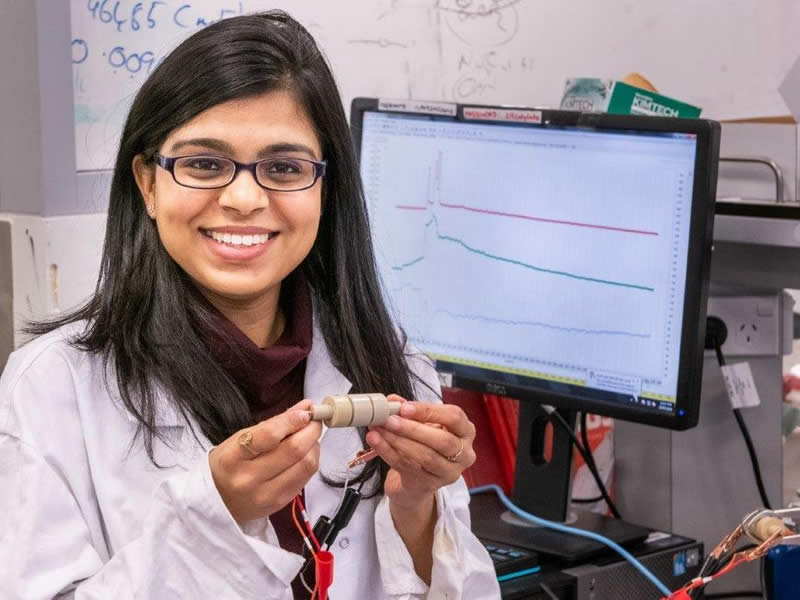

Dr Shalini Divya

Dr Shalini Divya

Tasmanlon/ Wellington UniVentures

A new aluminium-ion battery technology, offering a safer, sustainable, cost-effective alternative for grid storage and portable applications

Christopher Smith - Manaaki Whenua – Landcare Research

The Mushroom Smith - commercial-scale production of fungi traditionally collected and eaten by Māori.

Christopher Smith, mycologist and founder of ‘The Mushroom Smith’

Christopher Smith, mycologist and founder of 'The Mushroom Smith', led the development of a programme at Manaaki Whenua – Landcare Research to investigate the commercial-scale production of fungi traditionally collected and eaten by Māori.

Over three years, Christopher developed a process to successfully produce three unique species of New Zealand mushrooms at commercial scale. He identified nutritional profiles, a neat fit within the growing global trend for protein-rich meat alternatives, and a commercial appetite from local high-end restauranteurs through his endeavours.

Unravelling the mysteries of New Zealand native edible mushroom production means agencies can now elect to invest in the technology and systems to bring mushroom produce to the hospitality industry as well as to iwi to feed the whanau.

As a technical consultant, producer and supplier of mushroom spawn, Christopher remembers harbouring entrepreneurial ambition from a young age. For this project, PreSeed Funding and a place in KiwiNet's Emerging Innovator Programme was pivotal, allowing him to pursue his investigations into native edible fungi at Manaaki Whenua – Landcare Research. Through the programme, he was able to collect wild specimens, initiate a breeding programme, undertake genomic investigation of strains, develop an artificial indoor production methodology at scale, quantify the production costs, and write it up in a 3-part series ready for use in setting up small-scale Māori-owned production units.

Although most New Zealand palates remain unacquainted with the unique tastes and textures of these fungi, the mushrooms had been known as a food source for Māori from pre-European times. Christopher has built strong relationships with tangata whenua throughout this work. In line with tikanga, he consults with iwi providing scientific and technical support, while iwi manage the primary production of this taonga and determine its future direction.

As The Mushroom Smith goes from strength to strength, Christopher is excited and curious to explore more entrepreneurial opportunities around genomics and the fantastic diversity of mushrooms in New Zealand. He says it has been an honour and a humbling experience to work alongside iwi and to effect authentic Tiriti engagement for this taonga. It is a rich future.

Ged Finch, XFrame™ Pty Limited / Wellington UniVentures

XFrame™: a recoverable and reusable framing system for the next generation of sustainable construction.

Ged Finch, Director and Research and Development Manager, XFrame™

Every component of the prefabricated and interlocking framing system is designed to be disassembled and reused at the end of the building lifecycle, aiming to reduce waste in the construction sector; a sector which currently generates approximately half of New Zealand's waste – about 1.6 million tonnes every year.

XFrame™ has experienced rapid growth supported by investment, expertise and connections through Wellington UniVentures, KiwiNet and Innovyz – and recently completed a successful, and oversubscribed, maiden capital raise.

XFrame™ Director and Research and Development Manager, Ged, and his team have completed multiple prototype buildings and projects. To date they have sequestered 20 tonnes of CO2 and made available 1500m2 of fully interchangeable and reusable wall framing panels (alongside 550 swappable wall lining panels). When compared to conventional building techniques XFrame™ has reduced the quantity of waste sent to landfill at the time of construction by 86% and achieved a direct material recovery and reuse rate of greater than 96%.

Tests indicate that XFrame™ can be deconstructed 40% faster than conventional building methods. Importantly, these constructed parts do not require 'processing or cleaning' - they are ready to be directly reused. The result is a time saving of more than 50% to recover and reuse building materials.

XFrame™ has been deployed in Otago, Canterbury, Wellington, Auckland and Adelaide (in a housing development, with the support of key partners). This year further projects are planned in the United Kingdom, and new markets including the US will be explored, as well as diversification into office furniture.

Dr Matheus Vargas - Orbis Diagnostics/ University of Auckland

Orbis Diagnostics makes complex medical testing simple and accessible wherever and whenever needed to help re-enable safe travel amidst a pandemic

Dr. Matheus Vargas, CSO of Orbis Diagnostics

Dr. Matheus Vargas, CSO of Orbis Diagnostics, has developed an innovative ‘lab on a disk’ testing platform to provide a quick and accurate antibody measurement to assess an individual’s immune response to past SARS-CoV-2 infection or a COVID-19 vaccine. The unique platform has been specifically designed for use at high-volume, non-laboratory point-of-need locations.

In the last two years, Orbis has pivoted twice; first from milk composition to cow ovulation and pregnancy, then to COVID-19 immunity. Matheus has been key to driving Orbis’ innovations, from early days analysing milk, to his PhD project creating Orbis’ progesterone sensor, to his leadership as Chief Scientific Officer in developing Orbis’ microfluidic quantitative immunity test (QIT) for antibodies to Covid-19.

Orbis’ mission is to make complex medical testing simple and accessible at point of need. Orbis’ rapid, robust QIT will be a critical tool to safely reopen borders and keep communities safe during a pandemic. Since pivoting to Covid-19 immunity one year ago, Matheus has transformed ideas and aspirations to reality with impact. Orbis has successfully closed its latest capital raise and has entered into an exclusive partnership with leading global biometrics company IDEMIA, whose eGate technology is in airports worldwide. Orbis aims to deploy its QIT in a major international airport by the end of this year as an added screening and risk mitigation strategy. The MacDiarmid Institute and the Dodd-Walls Centre have been long-term supporters of the Photon Factory and its commercial researchers such as Matheus.

Dr Shalini Divya - TasmanIon/ Wellington UniVentures

A new aluminium-ion battery technology, offering a safer, sustainable, cost-effective alternative for grid storage and portable applications

Shalini Divya, Co-Founder and Chief Technology Officer, TasmanIon

Born and raised in India, the fourth-largest energy consumer globally, Dr Shalini Divya’s work into more sustainable battery technology stemmed from her energy poverty awareness. Energy poverty affects more than 400 million people, and limits access to food and water, education and employment and negatively impacts health and hygiene.

Shalini completed her BSc (Hons) in Chemistry from University of Delhi before completing her MSc in Chemistry at Birla Institute of Technology in Mesra. In February 2017, Shalini received the Victoria University of Wellington Doctoral Scholarship and started her PhD with Professor Thomas Nann, previous Director of the MacDiarmid Institute for Advanced Materials and Nanotechnology.

Shalini's research breakthrough came when researching more sustainable battery technology for her PhD. She discovered a new cathode material for aluminium-ion batteries that outperforms most other energy storage materials in aluminium-ion battery literature. Aluminium-ion batteries use electrolytes that are non-flammable and therefore suited to a range of applications. In addition, aluminium is the most abundant metal in the Earth's crust, non-toxic, and easily recyclable.

With a growing demand for more sustainable technologies that increase storage supply and reduce our carbon footprint - the commercial potential of Shalini's discoveries was clear. Shalini worked closely with Wellington UniVentures and the MacDiarmid Institute to drive the project to the investor level, progressing the establishment of a new spin-out company, TasmanIon. Shalini has also secured a place on KiwiNet's Emerging Innovator Programme to enhance her entrepreneurial skills and connections and advance the commercialisation of her new technology.

While aluminium-ion battery technologies are still in their infancy, Shalini is determined to create an entirely new battery class that does not rely on lithium - used for battery technology in electric vehicles (EV's), renewables and other applications. With supply constraints on lithium in the long term, TasmanIon has the impetus to compete against the cutting-edge incumbent and integrate into large markets already established, allowing for rapid growth. Aluminium-ion batteries can also be produced much cheaper than Lithium-ion batteries, with a more competitive and less volatile metal price. Shalini has also demonstrated that aluminium-ion batteries can be manufactured in existing production facilities; therefore, avoiding significant investments into new production technologies.

Researcher Entrepreneur Finalists

This award recognises an entrepreneurial researcher who has made outstanding contributions to business innovation or has created innovative businesses in New Zealand through technology licensing, start-up creation or by providing expertise to support business innovation.

Andrea Bubendorfer

Andrea Bubendorfer

Callaghan Innovation

Championing science and scientists for real value

Prof Johan Potgieter

Prof Johan Potgieter

Massey University

Inspiring entrepreneurial insurgency by creating a technology pipeline

Prof Ian Woodhead

Prof Ian Woodhead

Lincoln Agritech Limited

Advancing electrical and electronic engineering for agri and environmental sectors

Andrea Bubendorfer - Callaghan Innovation

Championing science and scientists for real value

Andrea Bubendorfer, Group Manager - Data and IoT Group, Callaghan Innovation

In addition to transforming inventions into ground-breaking technologies for industry, Andrea Bubendorfer has embraced a new role within Callaghan Innovation as an agent of change – championing other scientists to pursue their commercialisation dreams, to deliver great prosperity for New Zealand.

With co-inventor Andrew Best, Andrea's passion for deep tech was realised in MicroMaker – a new type of 3D printing to enable NZ businesses to participate in the lucrative global miniaturisation industry. It was enormously successful, garnering international accolades, interest from half a dozen investors, the inaugural Engineering New Zealand Engineering Innovation award and a finalist in the 2019 KiwiNet Awards Breakthrough Innovator category.

With KiwiNet PreSeed investment and places in KiwiNet's Emerging Innovator and Exponential Founder programmes Andrea learnt valuable commercialisation skills and developed a resilient, entrepreneurial mind-set. With her passion for cultural change, Vic Crone identified Andrea as someone who graciously and persistently tackled challenges head on, both in-house and in the ecosystem.

Andrea has been promoted to Group Manager to support the Data and IoT Group of over 40 people, through a transformational organisational change. She is well placed to do this, having worked on many strategic initiatives including a multimillion-dollar unique industry facing cleanroom in NZ. Andrea's bigger picture view celebrates the value of people, believing that we all win when we lift up as many people as we can. Andrea's outreach beyond her organisation is wide and she is proud to have created a thriving diversity and inclusion group at Callaghan Innovation.

Professor Johan Potgieter - Massey University

Inspiring entrepreneurial insurgency by creating a technology pipeline

Professor Johan Potgieter, Massey AgriFood Digital Lab, Massey University

Professor Johan Potgieter is at the centre of almost everything at Massey AgriFood Digital Lab. Johan has created a hub for some of the most outstanding innovation, robotics, IOT (Internet of Things) and 3D printing in the Southern hemisphere. You can find him guiding and advising students, staff, directing projects, and sharing his knowledge with the aspiring innovators of the future.

Prof. Johan Potgieter has developed a significant commercialisation portfolio with a strong drive to improve the New Zealand research and commercialisation landscape through strong business partnerships and end-users:

- Remote monitoring substation robotic platform for Transpower Ltd

- Within the New Zealand Product Accelerator engaging with and providing commercial technology solutions to a variety of companies within New Zealand

- FMCG product development for Zuru Ltd

- Developed a confectionary manufacturing process for a $500M revenue product

- Start-ups - MA Innovations Ltd, ISM Ventures Pty Ltd, Compress Tech Ltd

Prof Johan Potgieter has a well-established reputation for his work in educational robotics and have been inducted into the World Robotics Education and Competition (REC) Foundation Hall of Fame. Johan is being sought out by large companies that are looking to implement technology into their processes and framework.

Professor Ian Woodhead - Lincoln Agritech Limited

Advancing electrical and electronic engineering for agri and environmental sectors

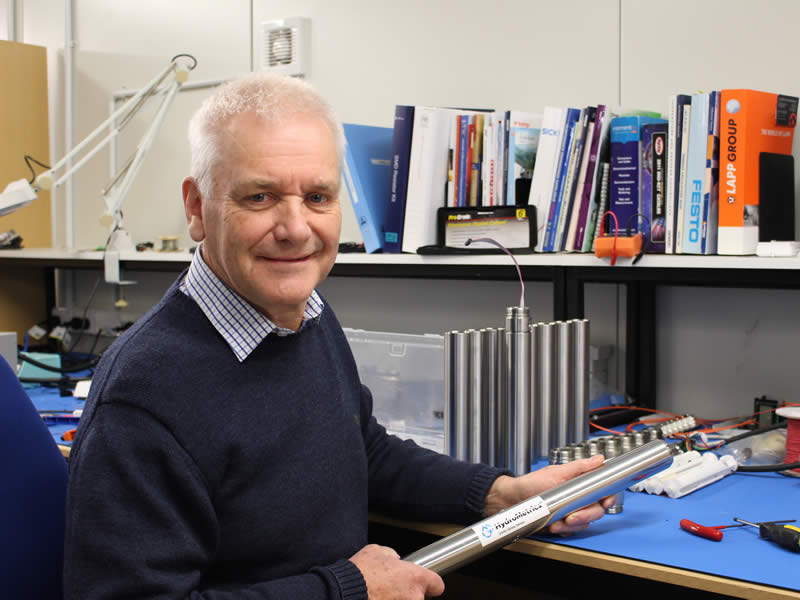

Professor Ian Woodhead, Chief Scientist at Lincoln Agritech Ltd

Professor Ian Woodhead’s outstanding contributions are embodied in the novel technologies he’s developed and the numerous advances in electromagnetic modelling, time domain reflectometry, microwave tomography and very high speed electronics he’s pioneered.

Ian has a PhD in applied physics and for 36 years has led R&D projects focused on electronic sensors. He is currently Chief Scientist at Lincoln Agritech Ltd.

Ian’s research has delivered a number of novel technologies to market via NZ’s export industries. Examples include:

- Patented electric fence performance sensor, manufactured and marketed internationally by Gallagher.

- R&D and software for Bluelab’s multi-award winning Pulse Meter.

- HydroMetrics™ UV-based groundwater nitrate sensor.

- Smarter irrigation – centre pivot radar soil sensor licenced to Autonomous Pivot (USA, Israel).

- Aquaflex a patented electronic soil moisture sensor, sold by OnFarm Data Ltd.

Ian is held in high esteem by his peers; his experience and breadth of knowledge is reflected in his various leadership roles including Return on Science Agritech Investment committee; Sensing, Robotics and Automation theme leader for the SfTI National Science Challenge; Science Oversight Committee for Overseer Ltd and the Predator Free 2050 Collaborative Group: Advancing our Knowledge, Innovation and Improvement. In 2014 Ian was made a Lincoln University Adjunct Professor, and in 2017 was awarded the Royal Society Te Apārangi Scott Medal.

Commercialisation Professional Finalists

This award recognises a commercialisation professional working within a New Zealand research organisation who has made an outstanding contribution to the commercialisation of publicly-funded research.

Dr Alex Tickle

Dr Alex Tickle

Otago Innovation Limited

Leading research teams to commercial success

Darja Pavlovic-Nelson

Darja Pavlovic-Nelson

Plant & Food Research

Sensing opportunities – capturing value from Plant & Food Research IP

Hamish Findlay

Hamish Findlay

Wellington UniVentures

A commercialisation expert, identifying and nurturing commercial outcomes to create impact

Dr Alex Tickle - Otago Innovation Limited

Leading research teams to commercial success

Dr Alex Tickle, Commercialisation Manager, Otago Innovation Limited

Dr Alex Tickle loves commercialising university intellectual property. She is a highly effective technology transfer professional with a global network, who forms strong teams for commercial success of life science innovations.

Alex holds several science degrees including a PhD in Organic Chemistry. Since joining Otago Innovation in 2003, Alex assessed and managed 131 projects, commercialising products in human and animal health including therapeutics, diagnostics, devices and new materials. Her latest deal being Otago Innovation's largest: a $14 million investment into Amaroq Therapeutics Limited. Amaroq is a start-up company that explores a new class of cancer drugs targeting long non-coding RNA, aiming to be in clinical trials in two years' time.

The key to leading research teams to commercial success has been Alex's ability to form, coach and nurture a broad range of talents and expertise across academia and business. Critically, she is an experienced negotiator and post-deal liaison manager, seeing her numerous deals generating revenues and translating innovations to products that are already (or soon) on the market.

A mentor to many, Alex's expertise is highly respected amongst her peers, business partners and researchers, making her an ambassador for not only Otago's but New Zealand's commercialisation of academic innovations, especially in the international biotechnology community.

Before immigrating to New Zealand and joining Otago Innovation over 17 years ago, Alex accumulated four years business experience in pharma industry, including leading the product and marketing management for Neuraxpharm.

Darja Pavlovic-Nelson - Plant & Food Research

Sensing opportunities – capturing value from Plant & Food Research IP

Darja Pavlovic-Nelson, Commercialisation Manager, Plant & Food Research

Darja Pavlovic-Nelson has been a commercialisation manager for less than two years and has already achieved a successful $1M capital raise to spin out Scentian Bio, securing the deal within just 15 months. Darja's passion, tenacity and excellent commercial acumen provide a great foundation for her future as an outstanding commercialisation professional.

Darja demonstrated excellent commercial acumen from the time she started in an IP role at Plant & Food Research, and worked closely with science teams and business managers to guide and coach them in developing IP strategies and in pulling together commercialisation plans. Working as an IP advisor, Darja supported a number of projects through to commercialisation.

She started providing business support to the science team behind Scentian Bio as a 'stretch' development project. Darja's entrepreneurial approach soon led to her being promoted to a commercialisation manager role taking a leadership role in the development of the Scentian Bio strategy.

Scentian Bio's technology is a platform that uses insect odorant receptors to provide rapid and ultrasensitive detection of target volatile organic compounds. It will provide novel chemical sensors with broad application across multiple markets (e.g. food safety/quality, explosive detection, cancer diagnostics, hazardous chemical monitoring, biosecurity, water quality, and alcoholic beverage production) with the global opportunity estimated to be worth more than $1B.

Capital raising is a new commercial activity for Plant & Food Research so Darja had to rapidly upskill herself through engaging with the investment community. She developed the business model and documentation, and conducted all the negotiations that led to acceptance of the deal by the Plant & Food Research Board, investors and of course the science team.

Hamish Findlay - Wellington UniVentures

A commercialisation expert, identifying and nurturing commercial outcomes to create impact

Hamish Findlay - General Manager Commercialisation, Wellington UniVentures

Growing up in a family of business owners and entrepreneurs, it’s no surprise that Hamish Findlay has dedicated his career to transforming great ideas into products and services that have impact on society.

A long career that has been honed over years in New Zealand’s universities, CRIs and government has given Hamish a unique skillset as a great translator of both the technical side and business side of commercialisation. The sheer breadth of his experience across the ecosystem makes Hamish uniquely positioned not only to support and enhance the commercialisation process, but to pass on the depth of his knowledge to his high-performing commercialisation teams.

Frequently leading teams to develop award-winning, high-impact technology solutions, Hamish’s leadership has resulted in the commercialisation of projects such as forensic analysis software (STRMixTM), the national poison database (TOXINZ), sustainable building materials (XFrameTM) and more. While at MBIE, his leadership and willingness to innovate supported the redevelopment of the PreSeed Accelerator Fund and Commercialisation Partner Network that makes up such a crucial part of the commercialisation landscape in New Zealand today.

Hamish’s deep technical understanding of IP commercialisation, coupled with his human approach is unique and makes him sought after in governance roles. In such positions, Hamish has a consistent track record of supporting successful capital raising activities across multiple spin-out companies, ensuring he will leave a lasting impact on the commercialisation landscape in New Zealand.

Commercial Impact Finalists

The commercial impact award celebrates excellence in research commercialisation delivering outstanding innovation performance and the potential for generating significant economic impact for New Zealand.

ACTIVLAYR™

ACTIVLAYR™

PLANT & FOOD RESEARCH AND NANOLAYR

Nanofibre skincare products made from New Zealand marine collagen - ActivLayr™ delivers bioactives into the skin using DermaLayr platform technology

First Watch

First Watch

WaikatoLink and CTEK

Protecting critical infrastructure from cyber attack

Aureo®Gold - Plant & Food Research, Zespri and UPL

Aureo®Gold - Plant & Food Research, Zespri and UPL

Aureo®Gold a new biocontrol product combating plant disease

ACTIVLAYR™ - Plant & Food Research and NANOLAYR

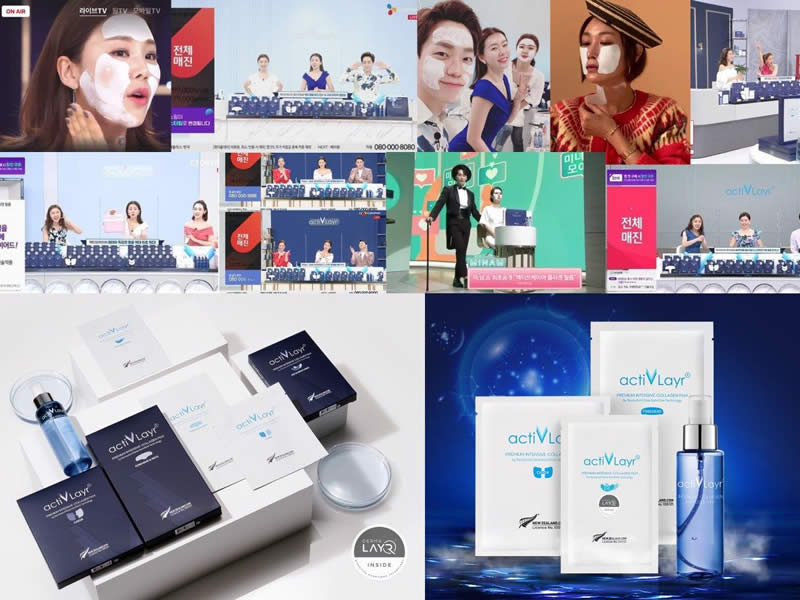

Nanofibre skincare products made from New Zealand marine collagen - ActivLayr™ delivers bioactives into the skin using DermaLayr platform technology.

ActivLayr™ is a unique consumer skincare product that leverages DermaLayr platform technology to deliver collagen and bioactives deeply and rapidly into the skin. ActivLayrs nanofibre matrix is formed from electrospun premium New Zealand marine collagen that can also carry a variety of different bioactive compounds. The nanofibre sheets dissolve rapidly when applied to wet skin, releasing the collagen and bioactives for rapid absorption. It has been clinically proven to outperform creams, gels and serums as a way to deliver effective and desirable benefits to the skin, such as tightening, brightening, protection and repair.

The collagen is extracted using a proprietary method developed by Plant & Food Research. This collagen is spun into nanofibres using NanoLayr's proprietary electrospinning technology, creating the ActivLayr consumer product. Strong and enduring collaboration between the two organisations has underpinned the commercial success, coupling technical expertise with a deep understanding of the market and customer needs.

ActivLayr™ was first launched in 2018 after which, the NanoLayr business model rapidly evolved towards producing scalable rolled-goods ingredients that are converted into finished consumer goods by International Original Design Manufacturers who service multiple cosmetics brands. Different formulations have been developed and commercialised through commercial partners in Korea, Hong Kong and China, as well as the ActivLayr branded products continuing to sell throughout Asia.

Growth has been exceptional for ActivLayr since its launch on Korean Home Shopping in late 2019, it has been regularly selling out with customer partners also growing and requesting new variants. NanoLayr, with ActivLayr, are set to meet their 5 year revenue targets, 2 years earlier than planned.

First Watch - WaikatoLink and CTEK

Protecting critical infrastructure from cyber attack

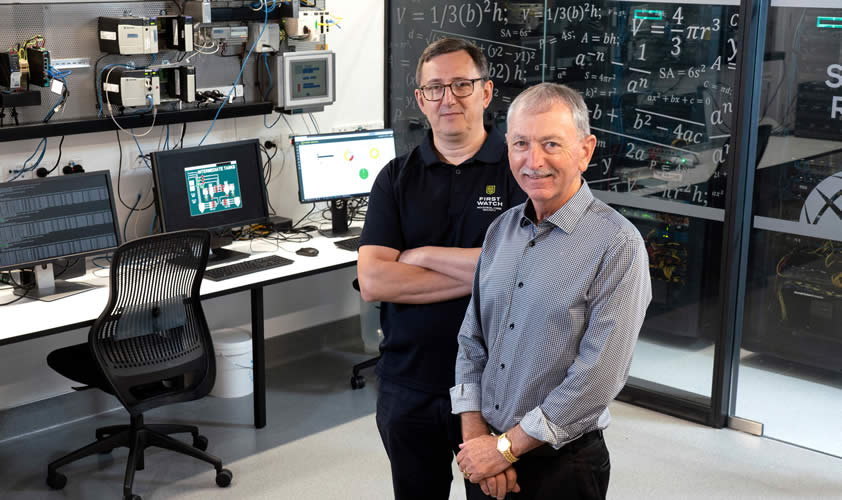

Alexi Ladur, Chief Technology Officer of First Watch (left) and Bob Stokes, Founder and Managing Director of First Watch and CTEK (right)

First Watch Ltd, jointly owned by WaikatoLink and Combined Technology Ltd (CTEK), was launched in late-2019 to protect industrial control networks from cyber attacks.

Cyber attacks on industrial control networks are increasingly made possible by the erosion of an "air gap" between industrial control systems' operational technology and the Internet: that is, the operational network used to be completely physically disconnected from the Internet. Industry 4.0, sensor networks and real-time partner support for efficient operations and pro-active maintenance offer substantial performance benefits to plant operators. However, because these networks were not originally intended to be connected to the Internet, they have multiple entry points for hackers and, therefore, are susceptible to security breaches. Because some of these systems control critical infrastructure, like water systems and manufacturing plants, the effects of security breaches have the potential to be very serious. Researchers from the University of Waikato working with WaikatoLink built a cybersecurity software suite to address this problem.

The project received PreSeed Accelerator funding from KiwiNet and investment from WaikatoLink and CTEK. Relationships built in Asia-Pacific helped First Watch secure seed round funding from, among others, SingTel Innov8 and NUS Singapore.

The Hamilton-based company has a team of 18, which is developing the product and securing pilots in dairy and critical infrastructure plants locally and in Asia-Pacific. The first commercial product is due to be launched in mid-2021. The University of Waikato continues to provide R&D for First Watch, researching the next generation of the product.

Aureo®Gold - Plant & Food Research, Zespri and UPL

Aureo®Gold a new biocontrol product combating plant disease

Greg Pringle, Business Development Manager, Plant & Food Research (left) and George Follas, Product Development & Regulatory Lead Australia & NZ, UPL

Aureo®Gold is a new biocontrol product, developed by Plant & Food Research and its commercial partner UPL, with the support of Zespri and Kiwifruit Vine Health (KVH).

Its launch by UPL in late November 2018 marked an important milestone in the New Zealand kiwifruit industry's ongoing efforts to better manage the kiwifruit disease Pseudomonas syringae pv. actinidiae ('Psa').

A more environmentally friendly product that is safe for bees, Aureo®Gold meets low residue requirements for export kiwifruit. It is already providing kiwifruit growers in New Zealand, especially organic growers, with an important tool in their Psa management toolbox and demand for the product has been consistently high since launch.

Plant & Food Research and UPL have begun commercialisation offshore to meet the demands of kiwifruit growers globally, where kiwifruit is grown on more than 400,000 hectares, most of which are affected by the Psa disease.

UPL is now exploring expanding Aureo®Gold to other territories and for other disease targets through complementary trials in several countries, with a commitment to register the product accordingly.