2019 Awards Finalists

The KiwiNet Awards celebrate heroes in research commercialisation — those individuals and organisations whose best practice approach is changing the innovation landscape in New Zealand. We congratulate the 2018 finalists!

View the press release and finalists below

Norman Barry Foundation Breakthrough Innovator Finalists

This award recognises an upcoming entrepreneurial researcher who is making outstanding contributions to business innovation or is creating innovative businesses in New Zealand through technology licencing, start-up creation or by providing expertise to support business innovation.

Andrew Best & Andrea Bubendorfer

Andrew Best & Andrea Bubendorfer

MicroMaker: a new 3D printing technology for high value miniaturisation

Dr Brendan Darby

Dr Brendan Darby

Revolutionising analytical spectroscopy by enabling analysis of cloudy liquids

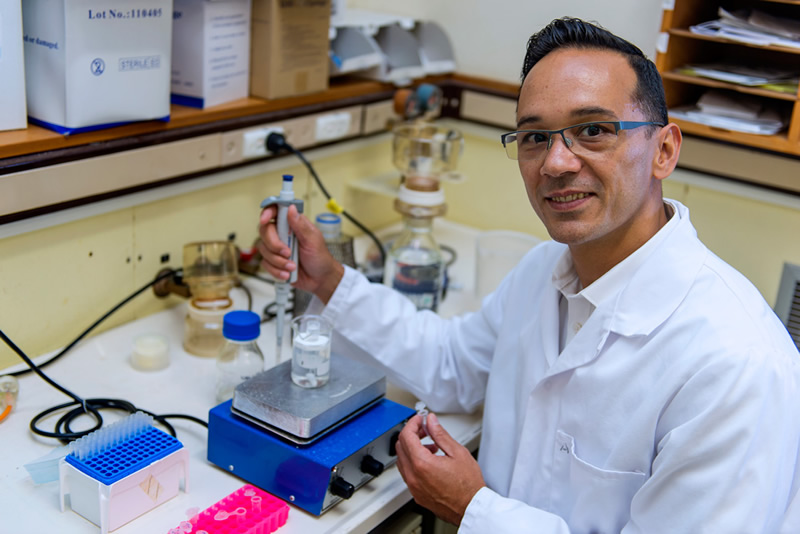

Dr Shalen Kumar

Dr Shalen Kumar

Precision diagnostics made faster, cheaper, and mobile

Andrew Best and Andrea Bubendorfer - Callaghan Innovation

MicroMaker: a new 3D printing technology for high value miniaturisation

Andrew Best and Andrea Bubendorfer are co-inventors of MicroMaker, a wholly new type of 3D printing for miniaturisation. This game-changing technology has the potential to open up miniaturisation as a new high value application in additive manufacturing, an industry that already exceeded 7 Billion USD in 2018.

Andrew and Andrea started by identifying microfabrication as an economically significant industry with easily exportable high value products. Recognising the high cost barriers to entry, they saw a gap in the market for an accessible approach. Using microfabrication principles and materials they created MicroMaker, enabling rapid prototyping to meet the demand for miniaturisation.

MicroMaker has attracted multiple international awards. Since its unveiling in September 2018, it won an exclusive launchpad at the IDTechEx show for emerging technologies (Silicon Valley, Nov 2018) and a select video interview by the chair. This was followed by a place in the RadLaunch class of 2019 with an invited Webinar, cash prize and funded travel to exhibit and present at the Big Ideas! Meeting (LA, Mar 2019).

Most recently MicroMaker received both a funded invited presentation and 3D print art exposition entry to Rapid + TCT, the preeminent event in 3D printing (Detroit, May 2019). MicroMaker has been showcased in all major 3D printing news sources as "a technology to keep an eye on".

The technology's development and commercial potential has MicroMaker sought after by investors and end-users. It is now underway with discussions to take this globally.

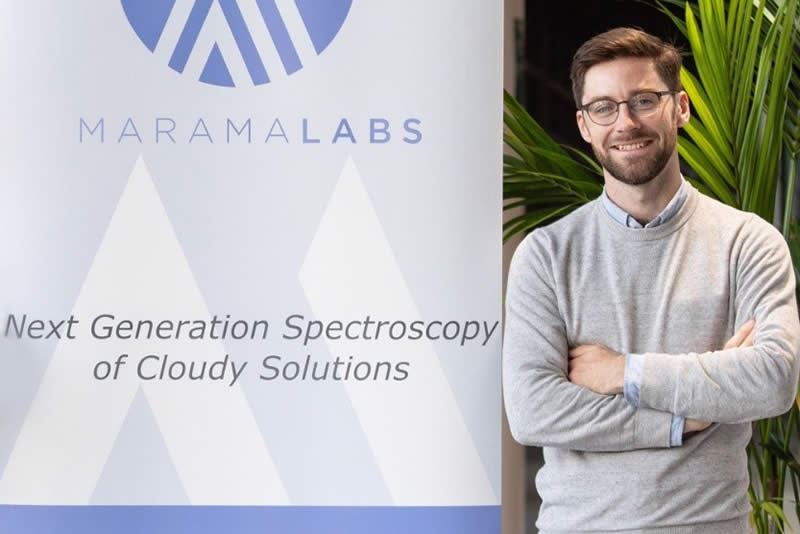

Dr Brendan Darby, Marama Labs

Visibility through the clouds – revolutionising analytical spectroscopy by enabling analysis of cloudy liquids

Dr Brendan Darby, founder-CEO of Victoria University of Wellington spin out company Marama Labs, has developed world first analytical spectroscopy technology that enables unprecedented insight into the composition of cloudy (or turbid) liquids, and drastically simplifies laboratory operations by eliminating costly sample preparation steps.

The Marama Labs technology is particularly pertinent for the food and beverage industry, where cloudy samples are common and product characteristics, such as colour, phenolics and hop content, are carefully crafted and a key driver of end-product value. The Marama Labs technology also has broad potential applications across a number of other industries that already use spectroscopy analysis for both compliance and product quality purposes.

During his PhD research, Brendan, a physicist, and MaramaLabs co-founders discovered a unique solution to the long-standing problem of measuring absorbance of light by molecules in the presence of highly scattering (cloudy) nanoparticles, using spectroscopic analysis. They quickly realised the discovery could have far and wide applications in industry, where sample cloudiness drastically reduces the ability to measure a liquid using light. Since beginning commercialisation work to develop the technology, Brendan and the team have further refined the technology and the company now has a first working prototype instrument and full commercial trials underway with two major wine industry players in both New Zealand and Australia.

Brendan has always been passionate about the application of physics to real-world problems, and alongside Marama Labs co-founders Dr Matthias Meyer and Professor Eric Le Ru, Brendan holds a vision for transformation of industry using innovative analytical instruments to demystify some of the complexities of creating high value products such as wine. Brendan sees the opportunity for this science to enable a new generation of master craftspeople by equipping them with new analytical tools and insights to create even better products.

Over the last two years Brendan has unflinchingly pursued his dream, having leveraged the commercialisation support network of Viclink, KiwiNet, Callaghan Innovation, and leading technology incubator, WNT Ventures, to ultimately found a start-up company as a commercialisation vehicle for his discoveries. Marama Labs has already attracted significant private investment and is set to take on the world of cloudy liquid analysis.

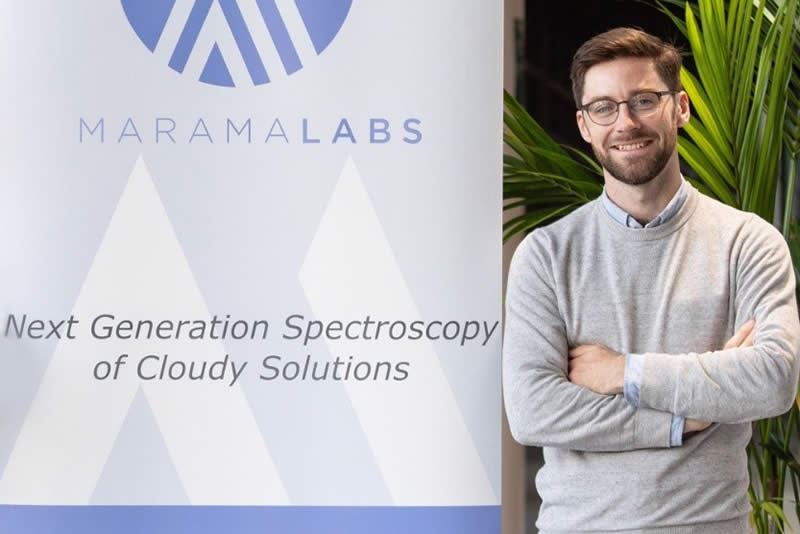

Dr Shalen Kumar, AuramerBio

Precision diagnostics made faster, cheaper, and mobile

Dr Shalen Kumar, Co-Founder and CEO of AuramerBio started developing aptamers (synthetic bio-receptors) to enable new high-end precision diagnostic solutions that is affordable and mobile. Shalen started research on Aptamer technology during his undergraduate studies at Victoria University of Wellington with a passion of providing high quality accurate, robust and sensitive medical diagnostic solutions for 3rd world communities and environmental monitoring.

In the US$10b POC biosensor market, AuramerBio is developing total solutions for mobile testing for illicit drugs and female fertility markets. AuramerBio has developed multiplex quantitative tests for up to 8 target molecules in saliva samples in under 3mins. AuramerBio also has Aptamers for steroid and protein hormones, environmental contaminants, amino acids, nutritional compounds, and various diagnostic biomarkers in its catalogue for future market expansion. AuramerBio has both National and International partner companies currently utilising Auramers Aptamers in their platform tech to offer novel diagnostic solutions for their market verticals.

Baldwins Researcher Entrepreneur Finalists

This award recognises an entrepreneurial researcher who has made outstanding contributions to business innovation or has created innovative businesses in New Zealand through technology licencing, start-up creation or by providing expertise to support business innovation.

Distinguished Professor Dame Margaret Brimble

Distinguished Professor Dame Margaret Brimble

Pioneering drug discovery and development

Professor Bruce MacDonald

Professor Bruce MacDonald

Revolutionising horticulture and healthcare with cutting edge robotic technologies

Dr Leonardo Negron

Dr Leonardo Negron

Bio-material research into innovative and unique products for the health sector

Distinguished Professor Dame Margaret Brimble - University of Auckland and Auckland Uniservices

Pioneering drug discovery and development

A pioneer in drug discovery in New Zealand, Distinguished Professor Dame Margaret Brimble has discovered a treatment for Rett Syndrome, Fragile X Syndrome and autism disorders. Trofinetide, currently entering phase III human clinical trials, is the first drug successfully developed by a New Zealand spin-out company and one of very few discovered in an academic laboratory.

Professor Brimble is founder of start-up biotech company SapVax, which is developing “first-in-class” cancer vaccines based on a novel peptide platform technology and funded by US accelerator BioMotiv. This work was awarded the 2018 George and Christine Sosnovsky Award for Cancer Therapy from the Royal Society of Chemistry.

Her work has recently resulted in two series of lipopeptide compounds being licenced to Living Cell Technologies (LCT) for the treatment of obesity and migraine.

An inventor on 50+ patents, Professor Brimble holds the Chair of Organic Chemistry and is Director of Medicinal Chemistry in the Schools of Chemical Sciences and Biological Sciences at the University of Auckland and Principal Investigator in the Maurice Wilkins Centre. She is past-President of the International Union of Pure and Applied Chemistry Organic Division, the International Society for Heterocyclic Chemistry and the RSNZ Rutherford Foundation.

She is a Dame Companion of the New Zealand Order of Merit for Services to Science, Fellow of the Royal Society London, the Royal Society of Chemistry UK, the NZ Royal Society Te Apārangi, the Royal Australian Chemical Institute and the New Zealand Institute of Chemistry. She is a recipient of the 2016 Marsden Medal, the 2012 RSNZ Rutherford Medal and the MacDiarmid and Hector Medals. She was the 2007 L’Oreal-UNESCO Women in Science laureate in materials science for Asia Pacific and won the 2014 Westpac Trust Women in Influence Award for Science and Technology.

Professor Bruce MacDonald, University of Auckland

Revolutionising horticulture and healthcare with cutting edge robotic technologies

An early enduring fascination with science fiction as a child led Professor Bruce MacDonald to dedicate his life to building robots to help people. Professor Bruce MacDonald has worked tirelessly and collaboratively to advance not only his own world-leading research but also that of the wider New Zealand research community working on robotics, sensors and automation.

As the founder and director of the University of Auckland's Centre for Automation and Robotic Engineering Science, Bruce has successfully led and launched substantial MBIE-funded agritech research programmes with industry partners in the Agritech sector, who are taking the new science and technology to the marketplace. The Autonomous Multipurpose Mobile Platform – a robot capable of picking and pollinating kiwifruit and flowers was developed by a multi-institutional team under Bruce's leadership in partnership with commercial partner Robotics Plus.

Bruce's reputation for excellent, high-impact research in robotics and eldercare has been recognised internationally, leading to major collaborations in Japan and Korea. His team is collaborating to develop assistive robotics technology in the aged-care sector with colleagues in the health sciences, and end-user partners such as Selwyn Foundation.

As Deputy Director of the Science for Technological Innovation NSC Bruce has inspired and guided dozens of Spearhead and Seed projects tackling complex and difficult science questions that, if answered successfully, will lead to the development of multiple novel technologies that will underpin a step change in the New Zealand economy.

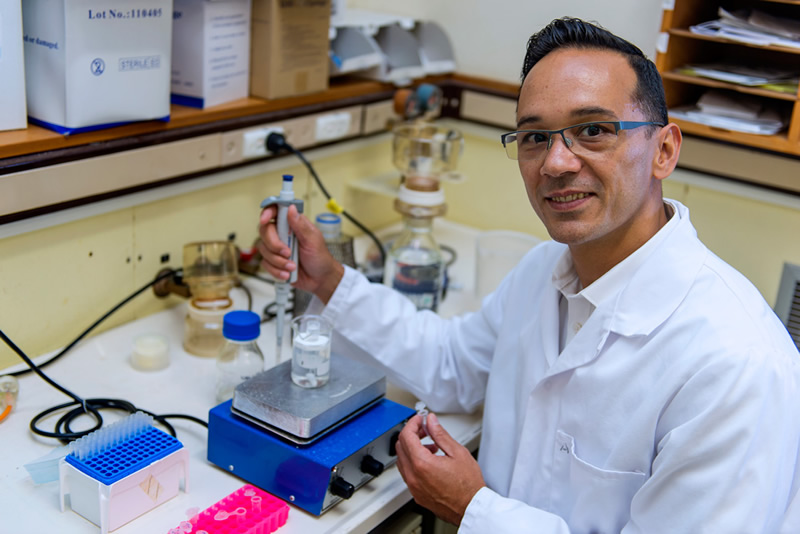

Dr Leonardo Negron, Callaghan Innovation

Bio-material research into innovative and unique products for the health sector

Dr Leonardo Negron, Distinguished Scientist and Team Leader of the Protein Bioprocessing team at Callaghan Innovation, develops innovative ingredients and devices for medical applications, using leading edge bio-material technology.

Dr Leonardo Negron, Callaghan Innovation

Bio-material research into innovative and unique products for the health sector

Dr Leonardo Negron, Distinguished Scientist and Team Leader of the Protein Bioprocessing team at Callaghan Innovation, develops innovative ingredients and devices for medical applications, using leading edge bio-material technology.

By applying his experience as a pharmacist and organic chemist, Leonardo is focused on spanning the entire commercialisation value chain, from fundamental research to complex products that make a real difference to health outcomes.

Through his secondment as Chief Technology Officer at Hi-Aspect, Leonardo led the work to take protein nanotechnology into formulations and devices for use in over-the-counter (OTC) medicines. This involved developing the scale-up manufacturing methods of protein nanofibrils, a world first, and characterising the technology for use as a delivery tool for active ingredients on the skin and in wounds.

The product development research involved incorporating the high surface-area protein scaffold into various hydrogel and emulsified formulations. This allowed the team to manipulate how active ingredients were presented to the skin surface and tailored their delivery to avoid premature loss of product while maintaining maximal contact with the affected area.

Hi-Aspect’s innovative protein nanofibril ingredient, Fibraspect300®, was first commercialised under the brand New Logic and is now in over 100 New Zealand pharmacies, for use in managing acne. Going forward, the company will look to, extend its New Logic range, launch up to two new product ranges in 2020 and continue developing more medicated products for the est. $8B OTC topicals market. The opportunities for this platform technology are wide and varied and Leonardo and his team will continue to work closely with the company to ensure developed products remain competitive and pioneering.

MinterEllisonRuddWatts

Commercialisation Professional Finalists

This award recognises a commercialisation professional working within a New Zealand research organisation who has made an outstanding contribution to the commercialisation of publicly-funded research.

Will Charles, Auckland UniServices and University of Auckland

Will Charles, Auckland UniServices and University of Auckland

Supercharging the commercialisation activities of the University of Auckland

Mark Cleaver, Massey Ventures and Massey University

Mark Cleaver, Massey Ventures and Massey University

Leading teams to transform New Zealand’s great food and agritech research capability

Geoff Todd, Viclink and Victoria University of Wellington

Geoff Todd, Viclink and Victoria University of Wellington

Commercialisation pioneer who has shaped the way scientific research is commercialised in New Zealand

Will Charles, Auckland UniServices and University of Auckland

Supercharging the commercialisation activities of the University of Auckland

Will Charles has had a significant impact on tech transfer in New Zealand over the past 13 years while leading the commercialisation activities at Auckland UniServices Limited.

Key achievements include: designing and implementing the best practice processes for Return On Science, the expert advisory available to all research organisations in New Zealand; setting up over $65M in venture funds via the Trans-Tasman Commercialisation Fund and University of Auckland Inventors Fund; together with top Australian universities attracting $200M of investment funding from the IP Group; and becoming a member of the $220M+ Medical Research Commercialisation Fund. Will led the sale of HaloIPT to QualComm, the US$10M investment into Soul Machines led by Horizon Ventures, and played an important role in PowerbyProxi’s recent sale.

During the past 30 months under Will Charles’ leadership, UniServices has accelerated its commercialisation activities resulting in 30 new companies, over 150 licensed patents, transacted or exited deals worth over $350m generating $61M in revenues for itself and its start-up companies. Its new companies have attracted $99M of external capital and generated 283 new jobs. Over the same period, UniServices has sourced and reviewed over 300 new ideas from the campus.

Will’s strategic ability and leadership have been core to the success of UniServices growing scale and attracting large pools of investment capital, both locally and externally.

Mark Cleaver, Massey Ventures and Massey University

Leading teams to transform New Zealand’s great food and agritech research capability

Mark Cleaver, CEO Massey Ventures, believes in the "good to great" approach, taking what we are already very good at and through the application of science, technology and commercialisation excellence, making it great.

For two decades Mark has led teams of commercialisation professionals, researchers, and industry to produce a consistent track record of deal making and some outstanding examples of commercialisation impact.

Mark has led deals with some of the world's largest and best known companies, generating a strong portfolio of commercialisation success in the food, agritech and animal health areas, reflecting the historical strengths of Massey University. His achievements include the trade sale of NZ Veterinary Pathology Ltd in 2015 and the acquisition by Nestle in 2019 of a formulation to address iron deficiency.

The ability to harness the passion of diverse groups for a common goal is what he sees as the key to unlocking the potential of New Zealand's R&D capability. "Our skilled team are experienced at working with a range of stakeholders to ensure that inventions make it to the market to benefit industry and society."

An important part of Mark's role over the years has been to help to develop the next generation of commercialisation professionals who work at the interface of science and business. "New Zealand has outstanding research capability and I want to make sure this is matched with excellence in commercialisation, through day-to-day investment in people and teams, as it will serve the country well in the decades to come."

Geoff Todd, Viclink and Victoria University of Wellington

Commercialisation pioneer who has shaped the way scientific research is commercialised in New Zealand

A commercialisation pioneer with a knack for spotting gaps in the science industry, Geoff Todd has had a profound impact on shaping the way scientific research is commercialised in New Zealand today.

From creating the first Angel Network in New Zealand in 2000 to participating in leadership, governance and mentorship positions in over a dozen deep tech start-ups, Geoff’s influence has been instrumental. Start-ups including HTS-110, Im-Able, Auramer Bio, iPredict and Wetox have benefited from Geoff’s experience, encouragement and innovative leadership.

A genuine enabler for careers in the New Zealand science community, Geoff actively encourages individuals to push into the sector and explore their potential. A strong advocate for women in science and commercialisation, Geoff’s guidance has supported many women who have stayed in the industry and risen to senior roles.

Geoff has led Viclink, Victoria University of Wellington’s commercialisation company, since 2014. In this time, Viclink grew from a small team of three to a well-resourced and highly effective business delivering nine spin out companies.

In 2018, Geoff led Viclink to establish the $10m New Zealand Innovation Booster fund in conjunction with Booster Financial Services. This innovative initiative was the first-time institutional investment had been applied to supporting New Zealand public sector technology start-ups.

PwC Commercial Impact Finalists

The commercial impact award celebrates excellence in research commercialisation delivering outstanding innovation performance and the potential for generating significant economic impact for New Zealand.

Sanford, Cawthron and SPATnz

Sanford, Cawthron and SPATnz

Transforming mussel aquaculture through hatchery technology and selective breeding

Plant & Food Research and Compac Sorting Equipment

Plant & Food Research and Compac Sorting Equipment

World-leading fruit grading and sorting technologies

Tectonus

Tectonus

Next generation earthquake protection

Sanford, Cawthron and SPATnz

Transforming mussel aquaculture through hatchery technology and selective breeding

New technology to grow mussel babies by the billion is enabling selective breeding to revolutionise mussel aquaculture in New Zealand.

You’d struggle to think of something we farm that doesn’t rely on the benefits of selective breeding. Yet mussel farming globally is an exception. Despite our $300M industry being the mainstay of NZ aquaculture, mussel farming has relied entirely upon unimproved, wild-caught juveniles or “spat”. That situation has now changed thanks to Cawthron, Sanford and SPATnz’s development of selective breeding and large scale spat production for one of our most valuable seafood exports, the endemic Greenshell™ mussel.

While the opportunity for selective breeding of Greenshell™ mussels was recognised in the 1990s, producing spat in a hatchery at scale has been a barrier for over 40 years. A concerted research effort by Cawthron and industry partners met this challenge. With support from the Ministry for Primary Industries Primary Growth Partnership, New Zealand’s first commercial mussel hatchery was developed by SPATnz at the Cawthron Aquaculture Park in Nelson, and now spawns over 2 billion eggs each month.

Cawthron’s MBIE-funded Cultured Shellfish programme developed the fundamentals of the selective breeding programme in anticipation of hatchery spat production. Sanford seized the opportunity, creating its subsidiary SPATnz, and partnering with Cawthron to form BreedCo Ltd. Under this partnership, the breeding programme has gone from strength to strength, and is now having a dramatic impact on New Zealand mussel farming and processing.

Selectively bred spat almost halve the growing time of wild mussels and are more efficient to process. Breeds specialised for anti-inflammatory activity and other new traits represent a massive future opportunity.

The industry is no longer completely reliant on variable wild spat for its production and has a powerful new tool to manage future risks.

Mussel food - microscopic plants growing in bioreactors as food for baby mussels

These 6 families of selectively bred mussels were grown side by side, but show strong family differences

Plant & Food Research and Compac Sorting Equipment

World-leading fruit grading and sorting technologies

Ensuring fresh produce looks, as well as tastes, good is key to the horticulture industry maintaining a supply of premium produce. Efficient sorting of fruit allows marketers of fruit and vegetables to grade produce effectively and efficiently, ensuring consumers aren't disappointed by the quality of their food.

Compac Sorting Equipment's technologies have revolutionised the sorting of fruit and vegetables, enabling the fresh produce industries to meet customer expectation for consistent blemish-free produce. Plant & Food Research and Compac work together to develop and enhance these technologies, ensuring new concepts and developments target industry needs. This seamless collaborative research approach allows continual improvements to Compac's technologies and was critical to the development of the Spectrim™ and Inspectra2™ technologies, released onto the market in late 2016. Through a shared vision, Plant & Food Research and Compac have worked together to build and validate these new technologies, which have allowed Compac to stay ahead of the market and double sales revenue in only four years.

Spectrim™ and Inspectra2™ has allowed marketers to reduce manual handling of fruit and vegetables, while increasing the volume of produce graded as premium. The Spectrim system is an optical and visual sorting platform, while Inspectra uses near-infrared (NIR) light to determine the internal characteristics of produce to allow efficient, automatic grading. Benefits of the system includes the high resolution detection of external and internal defects in 10-15 fruit per second as it moves along the grader. Sales of the Compac technologies have exceeded expectations in the two years since release, with sales of the system in over 50 countries, and have led to increased manufacturing volumes and capabilities at the Auckland-based factory.

Tectonus

Next generation earthquake protection

Tectonus brings to market a revolutionary earthquake resilient connection that allows buildings to withstand earthquakes and aftershocks - without requiring repair or replacement. Traditional seismic solutions are often one-off or require some sort of repair following an earthquake, leaving the building at risk whilst awaiting repair or demolition.

The Tectonus connection fits into any structure, new or existing, and acts like a spring – absorbing the earthquake forces with the added advantage of self-centring. After each earthquake or aftershock, the Tectonus connection will self-centre itself and the structure following shaking; always ready to protect for any future trembles.

Prof. Pierre Quenneville and Dr. Pouyan Zarnani led the research of Tectonus through a MBIE grant and the collaborative efforts of University of Auckland and AUT, with the support of UniServices and AUT Ventures. The research conducted has seen the connection tested in full scale demonstrations, showing the capability of the connection and the exciting opportunity to protect structures unlike ever before.

Tectonus connections can be seen in the exquisite new Nelson Airport Terminal that opened late 2018. Protecting the structure are 58 Tectonus connections. Future Tectonus projects in New Zealand include a medical facility that has been designed to be fully operational following a seismic event – the first of its kind. The company is set to announce their first international project in mid-2019.

The company is excited to bring New Zealand innovation to the global arena, helping protect communities and infrastructure for generations to come.

View of inside the Nelson Airport Terminal with Tectonus connections visible mid-way in the columns

Tectonus connection

Momentum Student Entrepreneur Finalists

The award recognises highly motivated New Zealand university students who have made significant progress developing an idea that can change the world.

These students are making outstanding contributions to commercialisation and innovation or has created an innovative business in New Zealand through technology licensing, start-up creation or by providing expertise to support innovation.

Connor Talbot

Connor Talbot

University of Auckland

ProstheteX - personalised 3D printed socket designs for amputees

Cynthia Hunefeld

Cynthia Hunefeld

Victoria University of Wellington

HerbScience: Back to the future

Christopher Walker

Christopher Walker

University of Auckland

Electroclear – removing underwater biofouling for marinas, boaties and aqua farmers

Connor Talbot, University of Auckland

ProstheteX - personalised 3D printed socket designs for amputees

ProstheteX are creating personalised 3D printed socket designs for amputees who are suffering pain, discomfort, and frustration, caused by their current prosthetics.

ProstheteX flexible custom design aims to eliminate issues that approximately 75% if all amputees face in their prosthetic journey due to prosthetic sockets, including skin issues because of their socket fit, and more serious complications such as oedema.

Connor Talbot, the founder of ProstheteX is a student at The University of Auckland and is in his final year of his Electrical Engineering degree. The venture was started with a co-founder, another undergraduate – Sebastian Weaver, who works as a technician for the New Zealand Artificial Limb Service (NZALS) and is majoring in Mechanical Engineering.

Connor Talbot says, "Current prosthetic sockets are developed with conventional manufacturing methods that can lead to hard, relatively inflexible sockets. We're aiming to achieve a better fit through personalised 3D printing for the ever-changing shape and size of amputee's residual limbs."

Since inception only four short months ago, the team has achieved wonderful traction. They have secured the world's foremost 3D printing expert, Professor Olaf Diegel and won several awards for their vision and values. Most notably, the team has snapped up the 'Research Prize' by UniServices at the 2019 Velocity Innovation Challenge, and, 'The Ultimate Start-Up' prize at Tech-Week Auckland 2019 hosted by Niesh and ATEED.

The team also walk the talk. They have connected to high profile amputees, testing their designs with NZALS, and are integrating themselves and their business heavily into the amputee community in New Zealand. With all this achieved in just four months, it is an exciting time for both the founders and the wider amputee community.

Cynthia Hunefeld, Victoria University of Wellington

HerbScience: Back to the future

Cynthia Hunefeld is on a mission to bring herbal medicine into the 21st Century with the help of modern science. With 20 years of experience in the field of integrative medicine and an academic background in ethnobotany, clinical herbal medicine and clinical research she identifies potential new medicines from a unique perspective.

Helping her father overcome an antibiotic resistant infection with the support of a plant extract was a defining moment for her, which has led to the discovery of an active constituent that can kill bacteria, and secondarily express poly-pharmacological actions to minimise the occurrence of single-step bacterial resistance, inhibit biofilm and bacterial adhesion, and ameliorate tissue damage at the same time.

Cynthia is currently studying towards her Masters in Innovation & Commercialization to establish the road for a novel plant-based for E. coli induced urinary tract infections (UTIs). She is aiming her innovation and commercialization pathway towards the development of a dietary supplement by 2020 and is working towards an evidence- based integrative medicine within the next 3 years.

UTIs are the most common bacterial infection world-wide that affects over 150 million people each year with a market value of 4.69 Bn. The World Health Organisation has indicated that there is a significant shortage of new medicines for E. coli induced UTIs and states that "Novel treatment regimens that are assembling non-toxic medicines are desperately needed".

The project has received recognition with a regional AMP scholarship and was awarded pre-seed funding by the Momentum advisory board.

Christopher Walker, University of Auckland

Electroclear – removing underwater biofouling for marinas, boaties and aqua farmers

University of Auckland bioengineers have developed an innovative way to get rid of the underwater biofouling that creates such a headache for marinas, boaties and aqua farmers.

Electroclear is using electric fields to disrupt small organisms' ability to live on selected underwater surfaces. It is a permanent, non-toxic solution that can be applied to a wide range of geometries.

"We became aware that biofouling was a big problem when we heard about the invasive fanworms in the Auckland harbour," says doctoral student Christopher Walker.

Walker, and fellow doctoral student and company partner Patrin Illenberger, (both in Auckland Bioengineering Institute's Biomimetics Laboratory) brought their bioengineering training to bear on the problem. They discovered that if they set up two separate electrodes underwater and created a fully encapsulated electric field, they could target and disrupt certain organisms.

Electroclear has been experimenting with several marinas: looking at ways to create electric fields on different surfaces - boat hulls, rope and key marine infrastructure. "The panels that had an electric field had no organisms attached after 50 days," says Illenberger, "while the others with no field had bryozoans, algae and barnacles on their surface."

With the positive results of their marina trials, Electroclear is pushing to get this into more applications.

"As an island nation with such strong ties to our ocean, we have a real chance here to lead the world in anti-fouling and biosecurity," says Walker.

Applications for this technology seem wide spread, from boat hulls to drainage systems. "The way forward is to dive into applications; we want this technology being trialled in aquaculture and marine infrastructure around the country."

Electroclear recently won funding and mentor support through the University's Entrepreneurship programme, Velocity, and is talking with research institutions and commercial partners to develop applications for both marine infrastructure and aqua farms. As well as Walker and Illenberger, the company includes Associate Professor of Engineering Science Iain Anderson, renowned for pioneering the University's world-champion, human-powered submarine, Taniwha.

"New Zealand has a unique ecosystem, if you add another creature from somewhere else, this society can be very much upset or disrupted," says Anderson.

Christopher Walker (Left)