KiwiNet News 12 February 2015

KiwiNet backed Ligar’s ground breaking science gets commercial boost with investment from Wallace Corporation

Hamilton, New Zealand, 12 February 2015

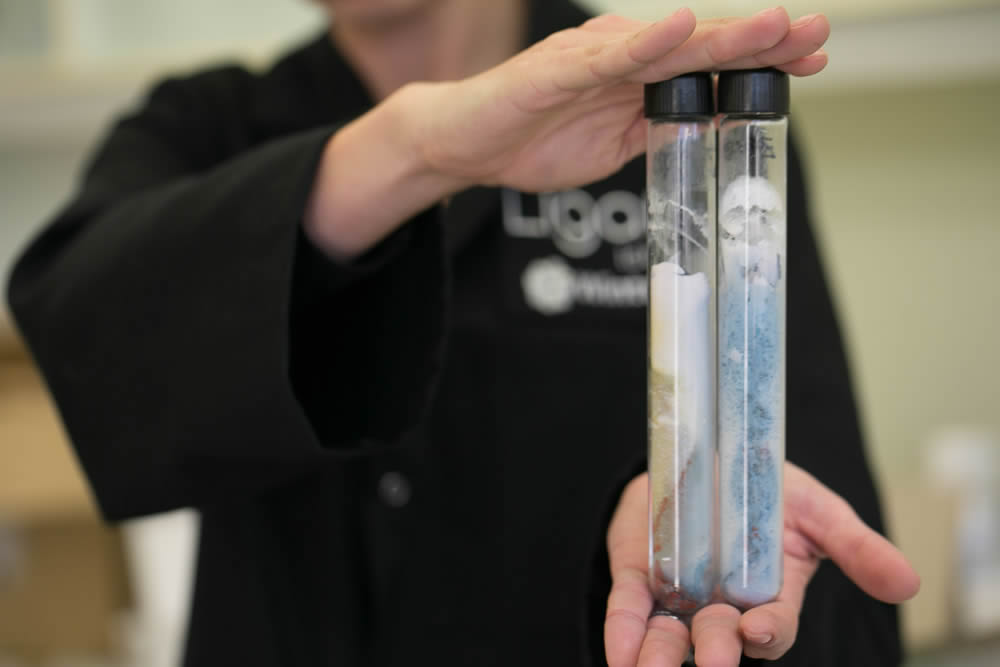

Molecularly imprinted polymers that pick out good and bad molecules from liquids attract further funding support to take innovation from lab to market

Nigel Slaughter, Chief Executive of Ligar

KiwiNet-backed Ligar, the developer of molecularly imprinted polymers (MIPs) for purification and extraction, has secured an initial investment of hundreds of thousands of dollars from Wallace Corporation, following KiwiNet investment support, to further accelerate commercialisation.

Ligar’s revolutionary technology solves a growing need for many industries to be able to extract both valuable and undesirable substances, whether those products are consumable liquids, dissolved minerals, water or ingredients used in manufacturing.

Ligar, a spin-out company that has been in development since September 2011, is based on a partnership between WaikatoLink Limited, the commercialisation and technology transfer company of the University of Waikato, and Wintec’s subsidiary LearningWorks, which is commercialising Wintec’s world leading research on molecularly imprinted polymers.

Over the past three years Ligar has received investment support from KiwiNet’s PreSeed Accelerator Fund from MBIE for three technology projects totalling $436,000. This funding was matched by WaikatoLink and Wintec.

Ligar has already successfully used its specially designed molecules to remove agrochemicals and smoke taint from wine; and is now investigating food and beverage purification and metal extraction. The company will use the new funds from Wallace Corporation to scale up the organisation and start a range of industrial trials with the aim of going to market with products later this year.

Graham Shortland, Chief Executive Officer of Wallace Corporation, New Zealand’s leading co-product partner to the New Zealand food processing industry says: "we’re always looking for innovations that will help us sustainably deliver greater value from our raw materials.”

“We first became interested in Ligar’s technology due to its potential to recover chromium used to tan hides, which makes good financial and environmental sense. We quickly saw that Ligar’s novel technology had commercial potential in a wide range of areas so we invested in the whole business. This investment is the second investment in a WaikatoLink spinout company in as many years.”

Duncan Mackintosh, the Chief Executive of WaikatoLink says, "We’re delighted to see another of our spin out companies go on to gain further investment from an industry player after first receiving investment and support from KiwiNet.”

Andrew Turnbull, Chair of KiwiNet’s Investment Committee says, “We were very confident backing Ligar along the way as it continued to demonstrate great potential and we could see a clear path from the lab to market. It’s a fantastic example of the value that can be created by publicly funded research organisations.”

Nigel Slaughter, Chief Executive of Ligar says: “in many industries great value can be derived by extracting valuable molecules more effectively or by removing unwanted molecules to improve product quality. We have identified a number of high potential market opportunities with industry partners around the globe, so the Wallace Corporation investment is very timely.”

He says one of the biggest opportunities is the extraction of high value substances from food and beverages and the removal of unwanted chemicals and contaminants.

“Wine is a good example; the Australian state of Victoria lost $100 million in 2009 alone due to smoke taint in wine caused by bushfires. Over the last few years that figure would total close to half a billion dollars, and that’s just one contaminant in one part of the world.”

Metal recovery from industrial processes is another area being investigated he says, “Currently twenty per cent of the chromium used in the tanning process is lost and ends up in the landfill. We can recover that chromium so it can be reused which not only has a financial payback, it also has some real benefits for the environment. This is particularly so in countries where tanneries don’t dispose of pollutants effectively and it ends up in rivers.”

The technology can also be applied to heavy metals contamination in food and water. The removal of arsenic from water used in production processes is another area the company is keen to investigate.

According to Slaughter, one of the highest value opportunities in this field is the extraction of rare earth elements. ”These metals are in huge demand worldwide as they’re used in all mobile phones and all sorts of high tech products including electric cars. The current processes used to separate these elements are expensive and environmentally hazardous, so if we could use our technology to simply filter the elements safely one by one it’d have a huge impact.”

The science behind Ligar originated and continues to be developed by Ligar’s Chief Scientific Officer Dr Miruna Petcu, supported by a polymer development team at Wintec.

Dr Pectu explains the technology, “Molecularly imprinted polymers, or MIPs, are like hungry plastic sponges that can be formed into any shape to exactly mirror and bind to its target in a solution. The targets can be as small as .05 of a nanometer which is many millions of times smaller than a millimetre. The MIPs allow us to pick out specific compounds of interest in a solution or mop up unwanted molecules, which we can then release to leave behind a purer product.”

Previously MIPs have only been able to sense and detect molecules, not release them to allow for effective filtering and extraction. Another unique aspect of Ligar’s proprietary technology that sets it apart is the ability to make the polymers in much greater quantities than possible before.

“Our scientific breakthroughs have allowed us to make kilograms and potentially tonnes of specifically designed MIPs in weeks or months, rather than just grams over several years. This opens up a wide range of commercial applications and allows industrial scale use for the first time,” says Dr Pectu.

Ligar is working with a number of multinational companies and is looking to partner with other commercial and research partners around the globe.

“We’re keen to work with leading players around the world who are keen to pursue new ways of doing things in food, metal removal, contamination, or anywhere else where molecules in the wrong place might be a challenge. We can’t investigate all the applications ourselves so we’re looking for research partners to help us too,” says Slaughter.

Further information:

Sandra Lukey

Shine Group (PR for KiwiNet)

Mobile: +64 21 2262 858

Email: sandra@shinegroup.co.nz

TV3 News Story

Kiwi company invents tiny cleansing 'sponges'

TV3 News - Thursday 12 Feb 2015